-

Biogas a sustainable replacement for LPG and Natural Gas

-

Offering Higest Quality Technical Fabrics Since 1960s

-

Installation in ONE day

-

The most cost effective biogas system available in the market

-

Scalable and Modular Digesters

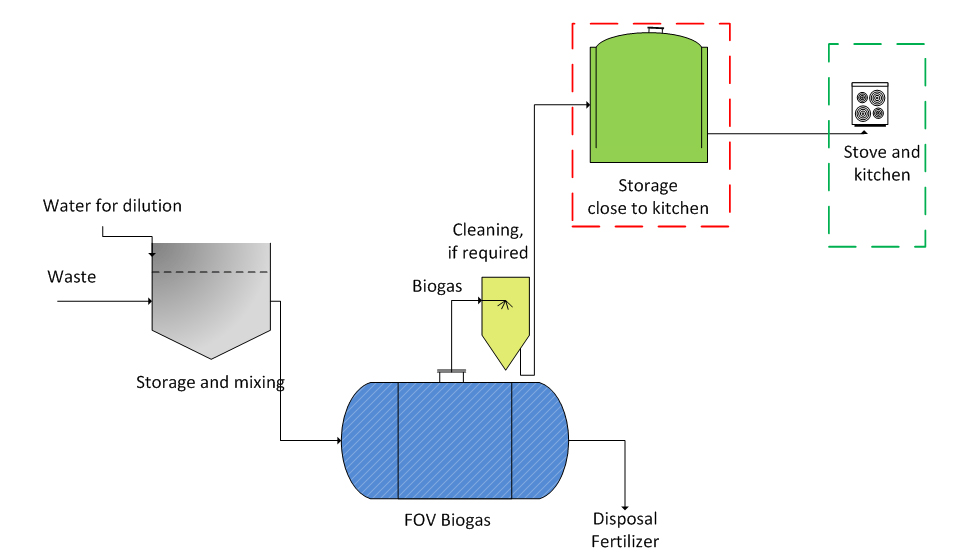

FOV Process

Process flow of FOV digesters

Process flow of FOV digestersBiogas plant is initially loaded with active inoculum to start the process. Once the methane gas formation starts, then the organic waste is fed in to the mixing tank to create a slurry form. The slurry is then fed to the FOV biogas reactor. On an average, the reactor will have a 30 days retention time. The feeding and digestate collection is a continuous process. The digestate generated post digestion can be used as organic manure.

In case of food waste, the waste is treated with a crusher to make slurry before feeding in to the digester. Organic waste such as liquid wastes and cow dung can be fed directly in to the digester with required amount of dilution.

The biogas generated can be used in several ways different ways

- Power generation using biogas generator (CHP)

- Biogas piped to the kitchen and used for cooking by using biogas burners

- For thermal applications such as heating in boilers

- For BioCNG generation. The generated gas can be purified and bottled in cascades and supplied to end users such as hotels and for other industrial applications. For BioCNG generation , the volume of gas required will be minimum of 1000 m3/day.